Service for All Machine Tools

CNC & Manual

Laser Calibration / Laser Alignment

&

Machine Tool Repair Services

By

Measurement & Machine Technology

Hands-on Experienced Professionals Since 1982!

In Your Shop, On Your Machine

Quality Service, Quick Response, Nationwide!

We Stand Ready to Help!

Are your machines making scrap - not parts?

Call Us - We Stand Ready to Help!

CNC Machine Tool Laser Calibration

Accuracy and peak performance of your CNC machine tools are keys to your success, increasingly customers are asking for tighter tolerances and reduced costs. Maximizing the performance of your machine tool is a must. Alignment, Ballbar Analysis and Laser Calibration will improve the performance of your machine tool, improve your product quality, enhancing your bottom line. Utilizing ballbar analysis, the accuracy of our laser calibration systems, combined with the reliability of our conventional measuring tools we completely analyze your machine tool, precisely adjust the alignments, laser calibrate the accuracy, and certify the results!

CNC Machine Tool Laser Validation

Here you see just one example of our CNC Machine Tool Laser Calibration Services in action. NIIGATA USA contracted us for Laser Analysis and Compensation of the Positioning Accuracy (including Backlash) on all axes of the newly installed NIIGATA HN80-D Horizontal CNC Mill and supply the customer a "Certification of Accuracy"; immediately following receipt of our certification the customer completed the purchase.

CNC Machine Tool Alignment

We have many years of hands on experience (since 1982) with alignment and calibration on an extremely large variety of machine tools, and do not have an affiliation with any one manufacturer, or specialize on any certain make or model of machine. Basic principles of machine design cross all lines. Therefore, we can align and laser calibrate all of your CNC machine tools and give you the complete CERTIFIED results.

If we can measure it we can fix it!

We fix what we find!

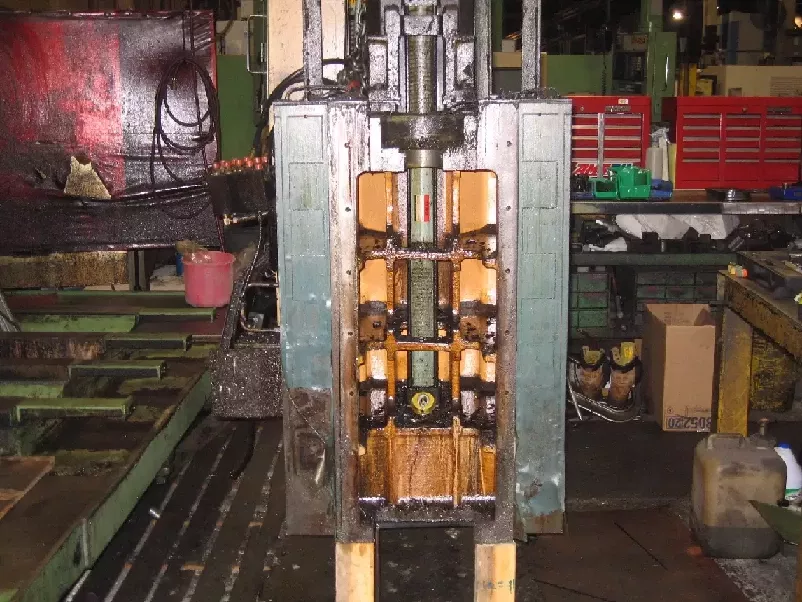

Seen here is the Z - Spindle Head of a MORI-SEIKI MV-80, showing the way surfaces needing repair.

Mori-Seiki MV80 Damaged Turcite

During a typical alignment and laser calibration job it is not unusual to encounter a machine with "hidden" problems. Having worked on a very large assortment of machine tools we can efficiently identify the problems and overcome them as necessary.

Mori-Seiki MV80 Scraping in New Turcite

This started out as an alignment and laser calibration. As you can see (previous photo) the TURCITE is damaged, after we properly replaced the turcite it was hand scraped (pictured above) for proper alignment.

Spindle Head Removed On-Site

During the work on the spindle head we removed the X, Y, Z ball screws and sent for rebuild and reinstalled. We verified the final GEOMETRY and laser calibrated the machine to finalize the project.

Precision Alignment and CNC Laser Calibration will

Take the Machine out of the Equation!

When you are machining parts “OUT OF TOLERANCE” it becomes a guessing game as to what is causing the rejection. You must eliminate potential sources one by one; the fixture, part program, cutting tools, material, even the operator comes into question as to what is causing the rejection. Precision alignment and laser calibration will establish that your machine is performing well within tolerance and you can stop wondering if it is the machine causing tolerance issues.

You have removed one variable from the equation when you know that it is not the machine.

Measurement & Machine Technology can perform all necessary alignment, adjustments and repairs required to bring it back into “LIKE NEW” condition!

When tasked with the alignment and calibration we precision level and align the machine base, check and adjust the gibs to “TIGHTEN-UP” the machine traversing, check squareness between all axes (adjust if required), check parallelism / perpendicularity of spindle to machine axes (adjust if required). Upon completion of the precise mechanical alignments we provide Laser Calibration AND Certification as to the condition of the machine.

When your “OLD” machine is performing like “NEW” you have Taken the Machine Out of the Equation.

Please keep in mind above is only a general procedure we use.

We adapt our machine tool alignment and laser calibration services to the individual machine and specific customer requirements.

Email us for an estimate specific to your needs.